We are moving beyond the current emphasis on lightness, rigidity, and strength to develop new functionality. Our refined design, manufacturing technology, and composite materials create even more added value and delight our customers.

- Is CFRP too expensive to use?

Closing the gap for replacement of existing products - Carbon fiber reinforced plastic (CFRP) has characteristics of both composite and anisotropic materials. We work with customers to exploit these characteristics and go from replacing existing components to getting rid of them completely through development of superior products.

- The Experts in P-QCD Mass Production

"Fujikura Rubber" - "Performance-based QCD" is our motto.

Fujikura Composites is devoted to performance improvement. As experts in mass-production manufacturing, we can meet customer demands for quality, price, and turnaround.

- Design Technology

-

- Technology developed through a long history of manufacturing rubber components and developing golf club shafts

- Simultaneous multilayer winding, which maximizes strength development rates to minimize the amount of material used

- Development of products that exploit the characteristics of cylinders

- Extensive use and application of a wide range of fibers and woven materials

- Numerical analysis (structure analysis, flow analysis, etc.), testing and rating capabilities (well-equipped physical and chemical test facilities)

- Processing Technology

-

- Stable characteristics and quality, cost reduction

- High dimensional accuracy and surface functionality for coatings, high-precision assembly, and machining

- Composite Material Technology

-

- Composites of rubber, resin, and metal, wide range of joining technologies

Exclusive to FUJIKURA COMPOSITES

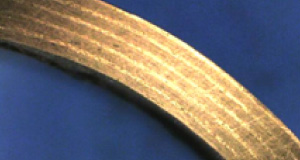

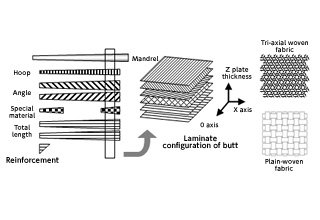

High-Strength Lamination Technology – Simultaneous Multilayer Winding

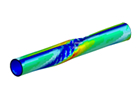

- We developed this lamination technique after analyzing sheet winding construction. It reduces the risk of delamination, a weak point of CFRP cylinder materials, and prevents damage, such as fiber buckling that occurs inside cylinders.

- The optimum lamination for the required characteristics, such as rigidity and strength, is determined through calculation and experimental findings. The quantity of material used is kept to a minimum.

* International patent WO2010/084809 A1

- High-Precision Molding of Internal and

External Diameter Dimensions -

Polishing is used to fabricate the outside diameter, while the internal diameter is molded by a high-precision sheet-winding method by which prepreg is wrapped around a mandrel.

Compared with hollow steel pipes, CFRP cylinders have extremely high-precision inner diameter dimensions and torsional buckling limits.

- New Possibilities for Lamination

-

As CFRP cylinders do not warp, there is no need for the symmetric lamination essential to plate materials.

This opens greater possibilities for lamination, allowing EI and GIp to be freely adjusted inside the same cylinder.

Unnecessary lamination can also be avoided, making it easier to design precisely and reduce the amount of material used.

A dream for any golfer who wants total control of ball direction

Precise ball control, taking the perfect trajectory to the target point, hitting more accurately with woods at maximum distance, striking the ball with ultimate accuracy with irons... We're working to create golf club shafts that make the dreams of golfers come true.

The shaft becomes a part of the golfer's body, making their strike just as intended.

We believe that every golfer has a different shaft that suits them best.

Every golfer has their own distinctive swing pattern.

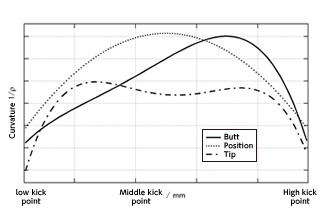

We have therefore optimized EL distribution for swing.

(Low, middle, and high kick point)

- Freedom for Tuning Rigidity

-

Exploiting the special characteristics of anisotropic materials, EI and GIp can be set to any value by varying the laminate composition at different points.

Curvature distribution curve

Curvature distribution curve Lamination pattern

Lamination pattern

- High-precision sheet

Winding -

Manufacturing method and equipment developed by Fujikura Composites.*

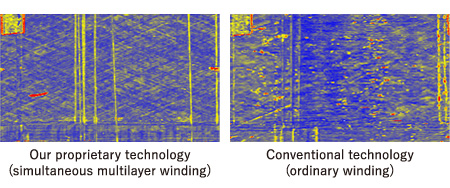

This process minimizes fiber distortion and voids inside the laminate.

These improvements deliver increased performance and stable quality.

* Japanese patent 4859975

- Internal observation by ultrasonic flow detector

-

- High Strength

- Brings out material characteristics in full.

20% better than conventional technologies.

- Increased strength from simultaneous multilayer winding

-

- High Rigidity

- Can be used with a range of fibers with low to high elasticity.

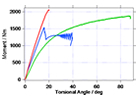

- Numerical analysis of torsional buckling

With thanks to ESI Japan Ltd.

-

- High Design Quality

- Outstanding numerical analysis techniques and production based on experimental results and trial manufacturing.

- Fuse point

* Special joint structure

* International patent W02011/024527 A1

-

- Reliable Quality

- Choose from a range of joining methods to suit your needs.

- Evaluation of strength by join position

-

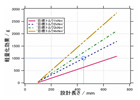

- Lightweight

- Massive weight reductions achieved by making body out of carbon.

- Effect of weight reduction on design length of carbon shafts by target torque (compared with iron shafts)

- Replacing Metal Rods

With CFRP Rods -

- Exposed resin on the surface means that CFRP rods are not very hard and their molding is less precise.

- They are less resistant to oil and chemicals than metal.

- Fujikura Rubber Research to

Improve CFRP Rods -

Plating CFRP surfaces

→ Improved surface hardness

→ Micron-level precision equivalent to metal (straightness, coaxiality)

→ Resin processing tolerance: ± 0.05

⇒ Plated CFRP rod processing tolerance: Max. ±0.005

→ Suitable for precision machinery

→ Increased resistance to oil and chemicals

- Connecting to Metal Fittings

-

→ Metal attachments can be used to prevent problems with screwing or drilling associated with CFRP

→ High-precision small-scale processing possible with a sliding spindle lathe

→ Proprietary technology produces highly reliable joins

-

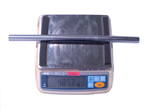

Steel 17.3 oz -

CFRP 8.1 oz -

Aluminum 34.2 oz -

CFRP 14.8 oz